3PL

Customized intelligence drives 3PL performance upgrades

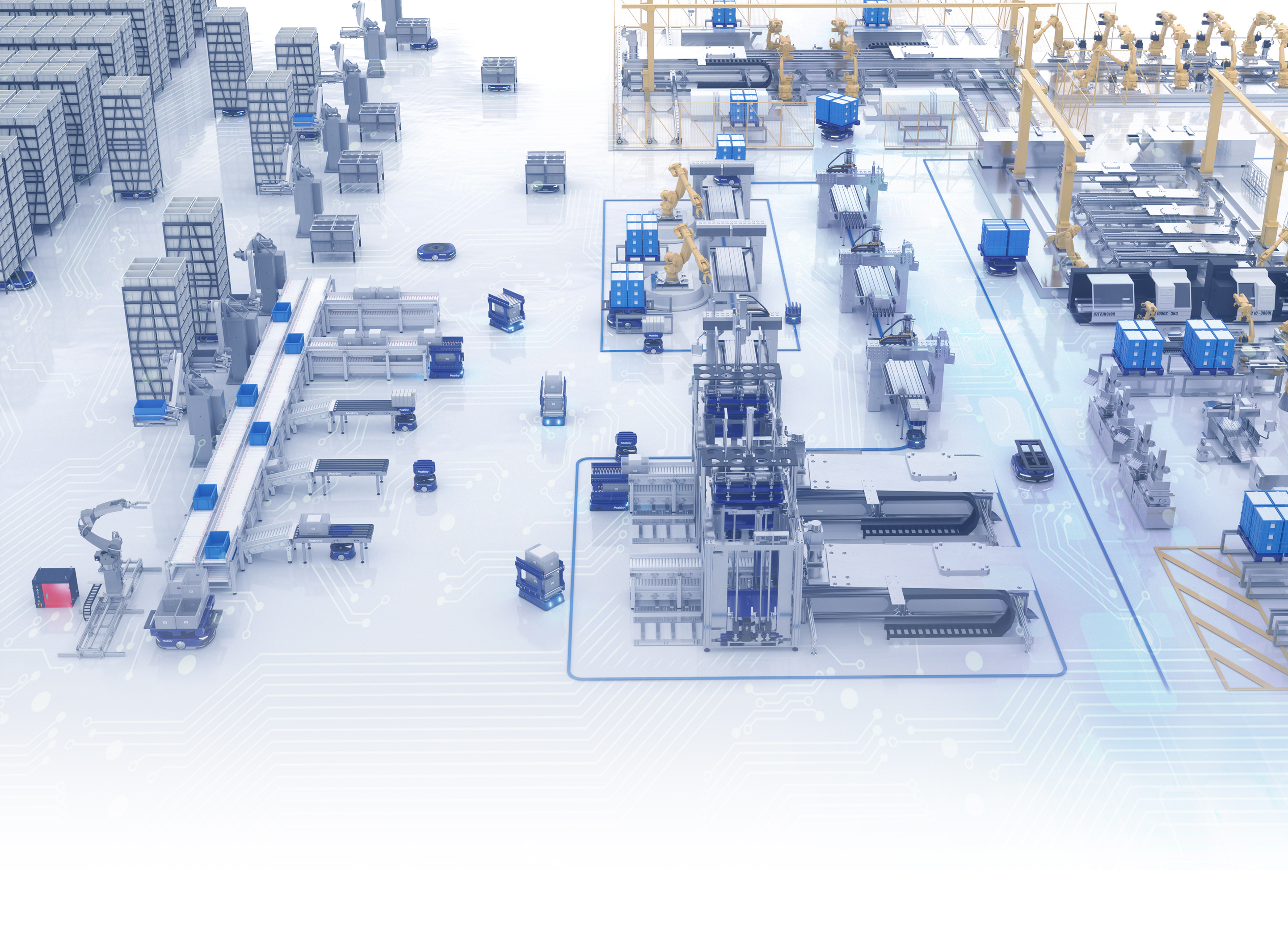

In the rapidly changing third-party logistics (3PL) field, efficiency, flexibility and scalability have become the core of enterprise competitiveness.

Successful cases in all categories of 3PL industry

Discover cutting-edge 3PL warehouse automation solutions with Mushiny. Our advanced 3PL warehouse system streamlines logistics and enhances efficiency, providing tailored 3PL warehouse solutions for your specific needs. Experience the benefits of automated 3PL operations that reduce costs and improve accuracy.

As a leader in warehouse automation in Australia, we are committed to optimizing your 3PL warehouse management processes. From inventory handling to order fulfillment, our technology ensures seamless operations. Transform your logistics strategy with Mushiny's innovative 3PL system and gain a competitive edge in the market. Explore the future of logistics automation today!

-

Australia PostCustomer Introduction:Australia Post is the largest logistics and warehousing enterprise in Australia. There are over 36,000 employees in the delivery, logistics, retail, and e-commerce networks of Australia Post, which annually delivers more than 4 billion parcels in around 1,150 outlets of parcel delivery across the country.Customer Pain:Low degree of automation, low efficiency of personnel operation, high labor cost.Solution1,200 ㎡(12,917 ft⊃2;), 45 Mushiny T series AMR robots are responsible for 4,000 kinds of products as well as inbound, storage and picking of 200,000 items.Customer ValuePicking efficiency: 300% improvement ;Safe and stable operation since its launch in 2019;Phase I 30 days to go live, 60 days to evacuate the site;Phase II completed 72 hours to move the warehouse with Mushiny remote support.

Australia PostCustomer Introduction:Australia Post is the largest logistics and warehousing enterprise in Australia. There are over 36,000 employees in the delivery, logistics, retail, and e-commerce networks of Australia Post, which annually delivers more than 4 billion parcels in around 1,150 outlets of parcel delivery across the country.Customer Pain:Low degree of automation, low efficiency of personnel operation, high labor cost.Solution1,200 ㎡(12,917 ft⊃2;), 45 Mushiny T series AMR robots are responsible for 4,000 kinds of products as well as inbound, storage and picking of 200,000 items.Customer ValuePicking efficiency: 300% improvement ;Safe and stable operation since its launch in 2019;Phase I 30 days to go live, 60 days to evacuate the site;Phase II completed 72 hours to move the warehouse with Mushiny remote support. -

YHGlobal supply chainCustomer Introduction:Founded in March 2012, Shenzhen YHGlobal Supply Chain Co., Ltd. is a collaborative enterprise dedicated to intelligent logistics supply chain.Customer Pain:High daily shipment, high manpower demand Difficult to recruit staff, high manpower costSolution:8,000 ㎡(86,111 ft⊃2;), 310 Mushiny T series AMR robots, 20,000 items stored, 400,000 items in stock, responsible for the most complex customer order processing.Customer Value:Personnel: 30% reduction ;Picking efficiency: 100% improvement ;27 days from the program to go live, 54 days to evacuate the site.

YHGlobal supply chainCustomer Introduction:Founded in March 2012, Shenzhen YHGlobal Supply Chain Co., Ltd. is a collaborative enterprise dedicated to intelligent logistics supply chain.Customer Pain:High daily shipment, high manpower demand Difficult to recruit staff, high manpower costSolution:8,000 ㎡(86,111 ft⊃2;), 310 Mushiny T series AMR robots, 20,000 items stored, 400,000 items in stock, responsible for the most complex customer order processing.Customer Value:Personnel: 30% reduction ;Picking efficiency: 100% improvement ;27 days from the program to go live, 54 days to evacuate the site.

How to Properly Run a 3PL Warehouse

Running a 3PL warehouse (third-party logistics warehouse) is a complex but critical task that requires strategic planning, effective implementation of technology, and adherence to best practices in supply chain management. With the increasing demand for e-commerce fulfillment, businesses are relying heavily on 3PL warehouses to ensure smooth operations. Whether you’re new to the logistics industry or looking to optimize your current operations, this guide will provide a comprehensive roadmap on how to properly run a 3PL warehouse effectively.

What Is a 3PL Warehouse?

A 3PL warehouse is a facility managed by third-party logistics providers that offer a range of services such as storage, inventory management, order fulfillment, and shipping. These warehouses play a pivotal role in the supply chain, serving as intermediaries between manufacturers and end customers. 3PL warehouses are widely used by businesses that want to outsource their logistics operations, especially in industries like e-commerce, retail, and manufacturing.

The Importance of 3PL Warehouse Management

Effective 3PL warehouse management is critical for meeting customer expectations, reducing costs, and maintaining operational efficiency. With the integration of advanced technologies such as AMR supply chain systems and warehouse automation solutions, businesses can significantly enhance their logistics operations. Let’s delve into the key strategies to properly run a 3PL warehouse while leveraging modern systems and solutions.

Key Strategies for Running a 3PL Warehouse

1. Implement a Robust 3PL Warehouse Management System (WMS)

A 3PL warehouse management system is the backbone of any efficient warehouse operation. This software facilitates real-time inventory tracking, order processing, and reporting. A well-integrated 3PL warehouse management system ensures seamless operations by automating manual tasks and reducing errors.

Features of a Good WMS:

- Real-time inventory visibility

- Automated order picking and packing

- Integration with shipping carriers

- Data analytics and reporting

- Compatibility with warehouse automation solutions

Using tools like Wavepoint 3PL warehouse management software, you can enhance your operational efficiency and stay ahead of competitors.

2. Leverage AMR Supply Chain Technology

Autonomous Mobile Robots (AMR supply chain) are revolutionizing warehouse operations by automating repetitive tasks such as picking, sorting, and transporting goods. AMRs reduce human intervention and improve accuracy, speed, and safety in 3PL warehouses.

Benefits of AMR Technology:

- Increased productivity

- Reduced labor costs

- Improved accuracy in order fulfillment

- Scalability for growing businesses

Companies investing in AMR supply chain solutions can streamline workflows and meet growing customer demands efficiently.

3. Optimize Space Utilization

Proper space management is essential in a 3PL warehouse to ensure smooth operations and reduce operational costs. Implement strategies such as vertical storage, zone-based organization, and efficient pallet racking systems to maximize space utilization.

Tips for Space Optimization:

- Use vertical shelving to maximize cubic space.

- Implement zone picking to streamline order fulfillment.

- Regularly audit storage layouts to identify inefficiencies.

4. Invest in Warehouse Automation Solutions

Warehouse automation solutions are critical for modern 3PL warehouses. These solutions include technologies like conveyor systems, robotic arms, and automated sorting systems that enhance operational efficiency and accuracy.

Advantages of Warehouse Automation:

- Faster order processing

- Reduced human errors

- Enhanced scalability

- Lower operational costs

In regions like Australia, companies adopting warehouse automation solutions Australia are seeing significant improvements in their supply chain efficiency.

5. Provide Tailored 3PL Warehouse Solutions

Every client has unique requirements, so offering customized 3PL warehouse solutions can give your business a competitive edge. For example, some businesses may require specialized storage for temperature-sensitive goods, while others may need rapid order fulfillment for e-commerce platforms like TikTok Shop.

Examples of Tailored Solutions:

- 3PL warehouse for TikTok Shop: Focus on fast order processing and real-time tracking.

- Temperature-controlled storage for pharmaceuticals.

- Kitting and assembly services for retail clients.

6. Focus on Scalability and Flexibility

As businesses grow, their logistics needs evolve. A successful 3PL warehouse must be scalable and flexible to adapt to changing requirements. Implementing modular storage systems and scalable software solutions can help you accommodate growth efficiently.

Key Practices for Scalability:

- Adopt cloud-based 3PL warehouse management software.

- Use flexible storage layouts that can adapt to varying inventory volumes.

- Partner with scalable shipping carriers.

7. Enhance Communication and Collaboration

Effective communication with clients and stakeholders is critical for running a 3PL warehouse. Use collaborative tools to ensure transparency and real-time updates.

Tools to Enhance Communication:

- Cloud-based collaboration platforms

- Integrated dashboards for client visibility

- Automated notifications for order status

8. Monitor Key Performance Indicators (KPIs)

Tracking KPIs is essential for measuring the success of your 3PL warehouse operations. Some important KPIs include:

- Order accuracy rate

- Inventory turnover ratio

- Warehouse capacity utilization

- Average order processing time

- By regularly analyzing these metrics, you can identify areas for improvement and make data-driven decisions.

9. Prioritize Customer Satisfaction

Ultimately, the success of a 3PL warehouse depends on customer satisfaction. Focus on timely deliveries, accurate order fulfillment, and transparent communication to build trust with your clients.

Best Practices for Customer Satisfaction:

Offer real-time order tracking.

- Provide flexible shipping options.

- Ensure consistent quality in order fulfillment.

Data Comparison: Manual vs. Automated 3PL Warehouse Operations

Emerging Trends in 3PL Warehouse Management

1. Integration with E-Commerce Platforms

With the rise of e-commerce, 3PL warehouses are integrating with platforms like Amazon, Shopify, and TikTok Shop to offer seamless order fulfillment. 3PL warehouse for TikTok Shop is an emerging trend, focusing on rapid order processing and efficient delivery.

2. Sustainability Initiatives

Sustainability is becoming a key focus in the logistics industry. 3PL warehouses are adopting eco-friendly practices such as using renewable energy, optimizing routes to reduce emissions, and implementing sustainable packaging solutions.

3. Use of Artificial Intelligence (AI)

AI is transforming 3PL warehouse systems by enabling predictive analytics, demand forecasting, and intelligent inventory management. Businesses leveraging AI gain a competitive advantage through improved efficiency and reduced costs.

4. Expansion of AMR Technology

The adoption of AMR supply chain systems is expected to grow, with robots taking on more complex tasks in 3PL warehouses, such as item picking, packing, and inventory audits.

Conclusion

Running a 3PL warehouse effectively requires a combination of strategic planning, advanced technology, and a customer-centric approach. By investing in a robust 3PL warehouse management system, leveraging AMR supply chain technology, and adopting warehouse automation solutions, businesses can achieve operational excellence. Whether it’s providing tailored 3PL warehouse solutions or integrating with platforms like TikTok Shop, the key lies in adaptability and innovation. As the logistics industry continues to evolve, staying ahead of emerging trends and maintaining a focus on efficiency and customer satisfaction will ensure long-term success for your 3PL warehouse.