Dive Deeper into Essential Details!

- What types of products can Mushiny's warehouse solutions handle?Mushiny's intelligent warehouse solutions are designed to handle a wide range of products, including cosmetics, skincare, haircare, and other beauty products. Our systems are highly adaptable and can manage various SKU types and sizes efficiently.

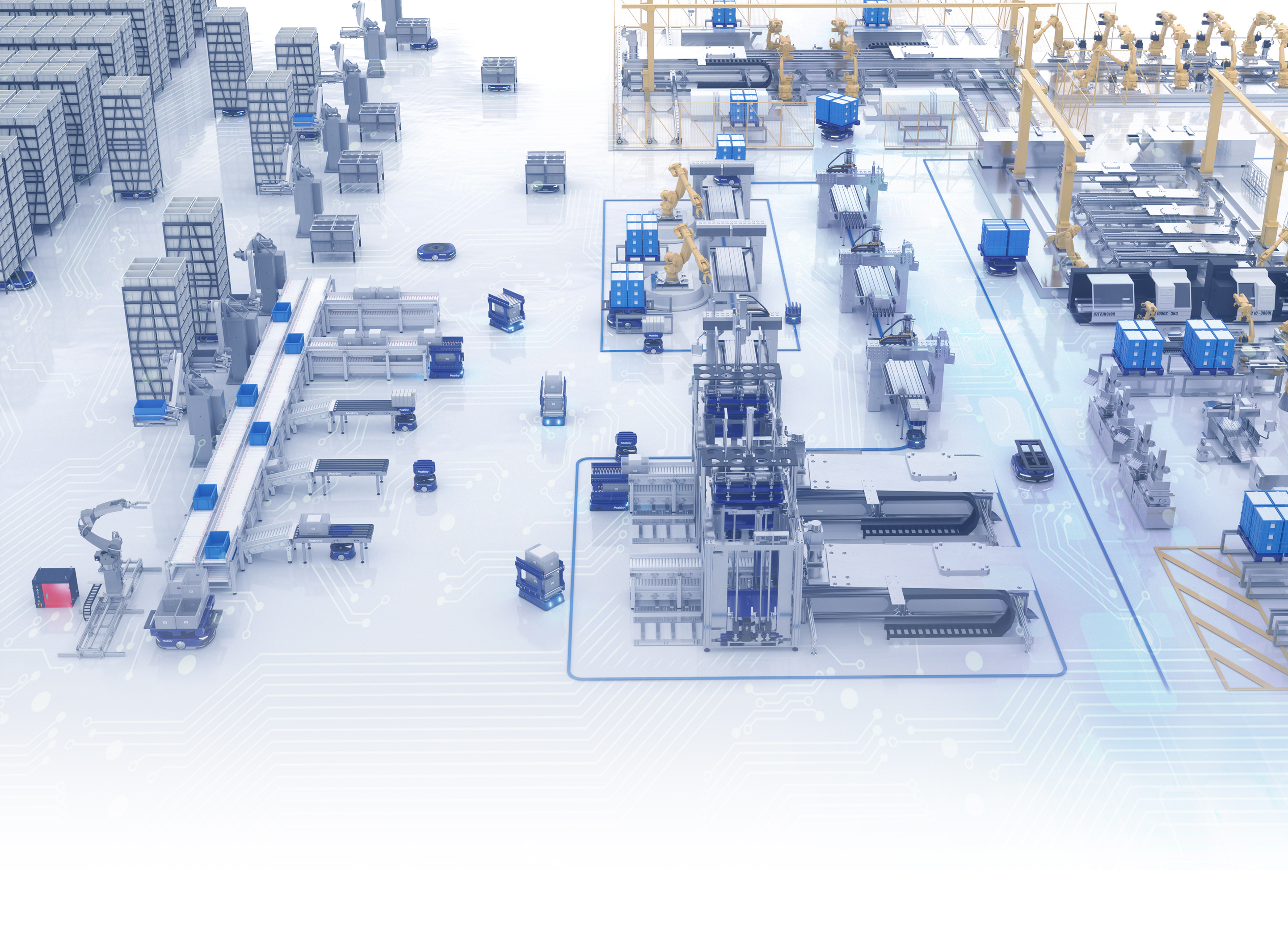

- How do Autonomous Mobile Robots (AMRs) improve picking efficiency?Our AMRs streamline the picking process by autonomously navigating the warehouse to locate and pick products. This reduces the need for manual labor, minimizes human errors, and significantly increases picking speed and accuracy. As a result, picking efficiency can be increased by more than twice.

- Can Mushiny's solutions integrate with existing warehouse management systems (WMS)?Yes, Mushiny's solutions are designed to seamlessly integrate with your existing WMS. Our systems are compatible with various WMS platforms, ensuring a smooth transition and enhanced operational efficiency without disrupting your current processes.

- How does the intelligent scheduling system work?Our intelligent scheduling system prioritizes orders based on urgency and optimizes robot paths according to inventory locations. This ensures that robots are dispatched in the most efficient manner, reducing travel time and increasing overall throughput.

- What are the benefits of choosing Mushiny's warehouse solutions?By choosing Mushiny, you gain access to cutting-edge technologies that enhance operational efficiency, reduce labor costs, and improve accuracy. Our solutions offer full process traceability, real-time monitoring, and seamless integration with existing systems, making them a valuable asset for any cosmetics warehousing operation.

- How can I get started with Mushiny's solutions?To get started, simply contact our team through our website or email. We will work with you to understand your specific needs and provide a customized solution that fits your warehousing requirements. Our experts will guide you through the implementation process and offer ongoing support to ensure your success.